Is Recycled Plastic Suitable for Marine and Waterway Construction?

At Kedel, we are passionate about innovating sustainable solutions that can withstand the challenges of modern construction. One of the most exciting applications of our technology is marine and waterway construction. The unique attributes of recycled plastic wood make it an ideal material for projects exposed to harsh aquatic environments.

In this blog, we’ll explore recycled plastic wood, why it is particularly well-suited for marine and waterway construction projects, and the types of projects it can be applied to, including walkways, fishing pegs, support piles, and more. We will also look at the sustainability aspect of choosing recycled plastic over traditional lumber.

What is Recycled Plastic Wood?

Recycled plastic wood, also known as composite lumber or synthetic wood, is an innovative material made from recycled plastic waste. Unlike traditional wood sourced from trees, recycled plastic is created by processing discarded plastic products. These products can include anything from plastic bottles and packaging to industrial plastic waste.

The manufacturing process involves cleaning and sorting the plastic materials, shredding them into granules, melting them with specific additives, and moulding them into shapes that mimic the appearance and functionality of natural wood. The result is a versatile, durable, and eco-friendly alternative that offers substantial benefits over traditional wood.

Why Is Recycled Plastic Wood Ideal for Marine and Waterway Construction?

Marine environments are among the most challenging settings for construction materials. Structures in these areas are constantly exposed to water, high humidity, salt, and the ever-present threat of rot and decay. While widely used, traditional wood requires regular maintenance treatments to counter these conditions, which can be both costly and environmentally detrimental.

Recycled plastic wood offers a compelling solution to these challenges for several reasons:

Impervious to Water and Rot

One of the primary advantages of recycled plastic wood is its imperviousness to water. Unlike traditional wood, which absorbs moisture, synthetic wood remains unaffected by prolonged exposure to water. This makes it an ideal material for marine applications where humidity and water contact are constant concerns.

Furthermore, recycled plastic wood is resistant to rot, mould, and mildew. Traditional wood can quickly degrade in moist environments, leading to structural weaknesses and safety hazards. In contrast, synthetic wood maintains its integrity and quality over time, making it a safer and more durable option.

Pest and Insect Resistance

Marine and waterway environments are also hotspots for various pests and insects that can wreak havoc on wooden structures. Recycled plastic wood is unappealing to these pests, ensuring that installations remain structurally sound and uninfested. This eliminates the need for harmful pesticides and preservatives, contributing to a healthier ecosystem.

UV Resistance and Durability

Exposure to sunlight can cause traditional wood to fade, crack, and become brittle over time. Recycled plastic wood, however, is UV-resistant, meaning it won’t degrade when exposed to sunlight. This characteristic ensures structures maintain their appearance and strength for years, even in harsh outdoor conditions.

Low Maintenance and Long Lifespan

The durability and resilience of recycled plastic wood translate into minimal maintenance requirements. Traditional wood demands regular staining, sealing, and treatment to prolong its life, whereas synthetic wood requires little to no upkeep. This saves time and resources and reduces the long-term cost of ownership.

Environmental Sustainability

Switching to recycled plastic wood is a significant step toward environmental sustainability. Using plastic waste, we divert material from landfills and oceans, reducing pollution and conserving natural resources. Additionally, the production process for synthetic wood is generally less energy-intensive than that for harvesting, processing, and transporting traditional timber. This combination of factors makes recycled plastic wood an eco-friendly choice for conscientious builders and developers.

Types of Marine and Waterway Construction Projects

The unique features of recycled plastic wood make it suitable for a diverse range of marine and waterway construction projects. Here are a few popular applications:

Walkways and Boardwalks

Walkways and boardwalks are standard features in coastal areas, lakesides, and riverfronts. Though aesthetically pleasing, traditional wood can become slippery when wet and requires frequent maintenance. Recycled plastic wood provides a safer, more durable alternative. It offers excellent slip resistance, even when exposed to water, ensuring safe passage for pedestrians.

Additionally, synthetic wood can be textured and coloured to resemble various types of natural wood, allowing for aesthetically pleasing designs without compromising on durability. Its resistance to saltwater, moisture, and UV rays means it will retain its appearance and structural integrity for much longer than traditional wood.

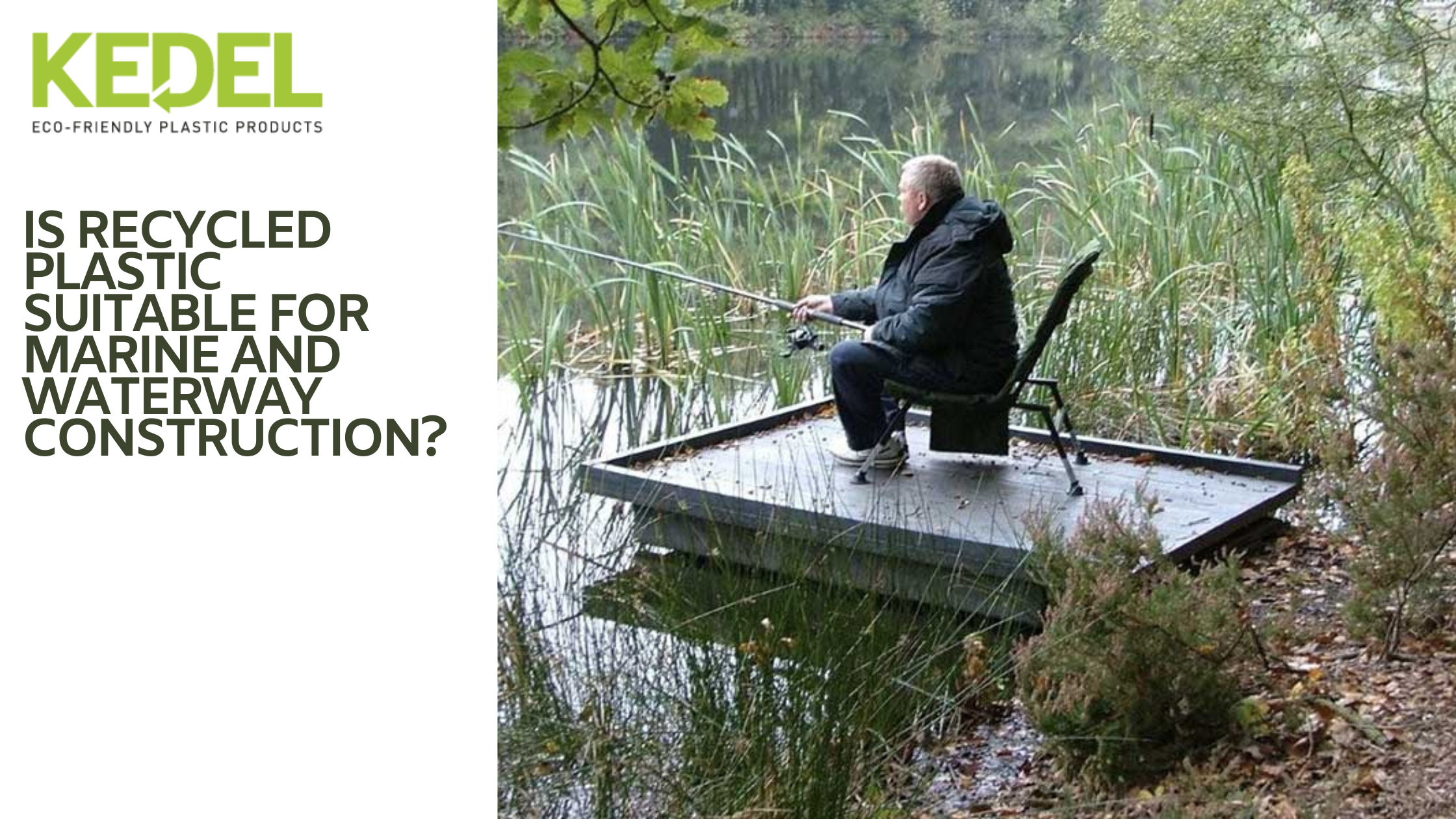

Fishing Pegs and Platforms

Fishing pegs and platforms are often exposed to harsh conditions, including constant water contact, exposure to fishing gear, and ever-changing weather. Recycled plastic wood is an ideal choice for these structures due to its robustness and resistance to decay. Anglers will appreciate the low-maintenance nature of synthetic wood, as it doesn't require regular treatments and won’t splinter or rot over time.

Using recycled plastic wood for fishing platforms also contributes to environmental conservation efforts, as it helps reduce the demand for hardwoods that are often harvested unsustainably from forests.

Support Piles and Piers

Support piles and piers are critical components in marine construction, providing the foundational stability needed for a variety of structures. Traditional materials like treated wood and steel are susceptible to corrosion, rot, and marine borer damage. Recycled plastic wood offers a cost-effective and sustainable alternative that outlasts these traditional options.

Synthetic wood piles and piers are resistant to the corrosive effects of saltwater and marine organisms, ensuring the longevity and stability of the structures they support. Additionally, they are easier to handle and install, as they are lighter than traditional timbers and metals, reducing the overall workload and costs associated with marine construction projects.

Coastal Erosion Control

Coastal erosion is a significant issue in many coastal areas, often requiring the construction of barriers, groynes, and other erosion control structures. Due to its durability and resistance to environmental stressors, recycled plastic wood can be used to build these structures. Synthetic wood barriers can help protect coastlines from the erosive forces of waves and tides, providing a long-lasting solution that requires minimal maintenance.

Floating Docks and Marinas

Floating docks and marina structures are constantly exposed to water and the elements, making durability and resistance to rot crucial. Recycled plastic wood's buoyancy and resistance to water damage make it an excellent material for these applications. It can withstand constant exposure to water and sun and the abrasive effects of boat hulls and other marine equipment.

Constructing marinas and floating docks with recycled plastic wood provides a sustainable and low-maintenance solution, ensuring these structures remain functional and attractive for years to come.

The Future of Marine Construction with Recycled Plastic Wood

As awareness of environmental issues and sustainability grows, adopting recycled plastic wood in marine and waterway construction is likely to increase. Technological advances will continue to enhance the performance and aesthetics of synthetic wood, making it an even more attractive option for builders and developers.

At Kedel, we are committed to providing innovative recycled plastic solutions that meet the demands of modern construction while prioritising environmental sustainability. By choosing recycled plastic wood for your marine and waterway projects, you are making a conscious decision to support sustainable practices and contribute to a healthier, more resilient planet.

Recycled plastic wood is an outstanding choice for marine and waterway construction due to its unique combination of durability, resistance to environmental stressors, and sustainability. Unlike traditional wood, which is prone to rot, decay, and insect damage, synthetic wood offers a long-lasting solution that requires minimal maintenance. Its wide range of applications includes walkways, fishing pegs, support piles, coastal erosion control, and floating docks, making it a versatile and practical material for various marine projects.

By opting for recycled plastic wood, you are not only ensuring the longevity and reliability of your structures but also supporting the global effort to reduce plastic waste and conserve natural resources. At Kedel, we are proud to offer high-quality recycled plastic products that help build a greener future. If you are considering using recycled plastic wood for your next marine or waterway project or want to learn more about our offerings, please contact us. Together, we can create durable, sustainable solutions that benefit both people and the planet.

.png)

100% Recycled Plastic

100% Recycled Plastic Will Never Rot

Will Never Rot 25 Year Guarantee

25 Year Guarantee Low Carbon Footprint

Low Carbon Footprint